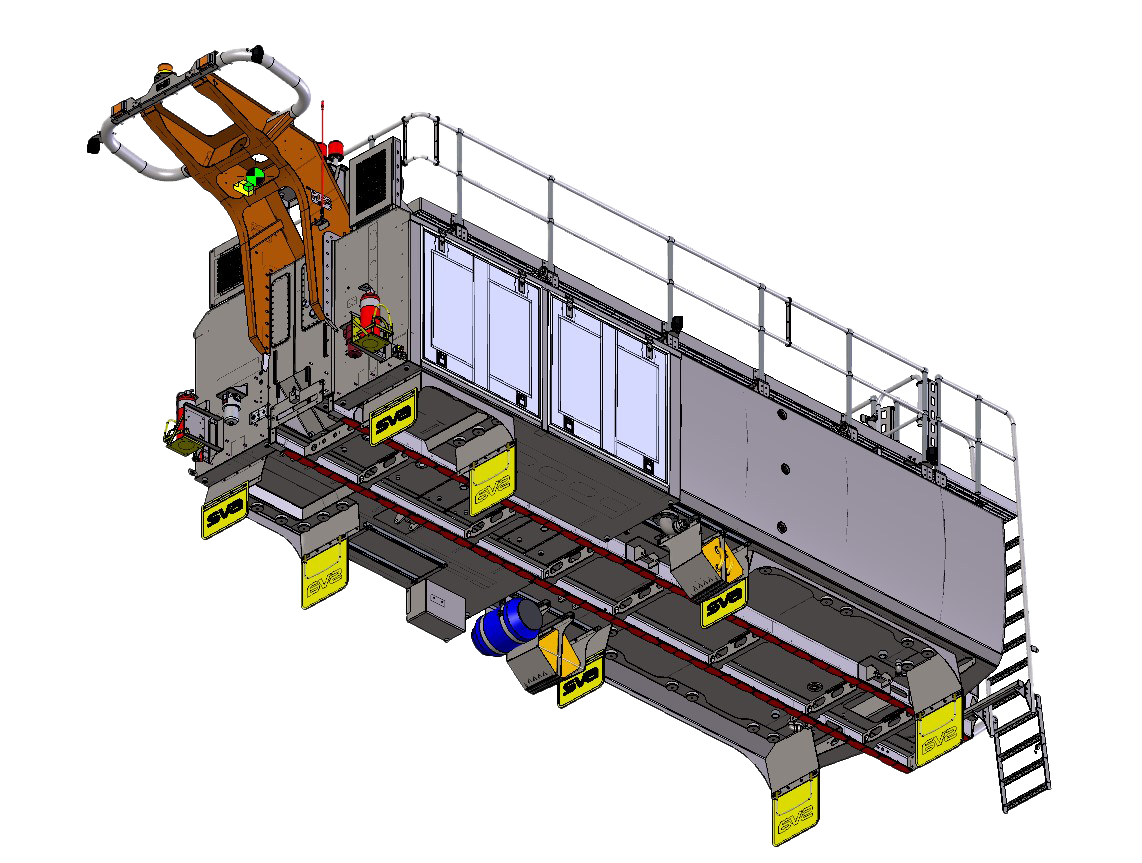

On-Highway Truck Service Modules

SVA’s on-highway truck service modules are designed and manufactured to be installed to a variety of makes, models and axle configurations. A range of capacity configurations, optional systems and components are available to tailor the module to specific service applications whether it is mobile equipment, drill support, ancillary equipment or fixed plant.

All SVA module design and manufacturing processes consider the actual working conditions and operator requirements of the mining applications the service truck will be operating in.

Chassis Configurations

SVA service truck modules can be designed to adapt to all makes and axle configurations of heavy duty carrier chassis’. In-house engineering analysis of the specific carrier chassis’ axle loadings ensure weight distribution is kept within the safe working limits specified by the truck OEM. SVA modules incorporate a robust under body structure that plays a crucial role in ensuring the tank shell is properly supported with full length support beams, urethane body pads and heavy duty chassis mounts. Selection of the highest quality manufacturing materials and components ensure SVA modules provide safety to the operator and longevity to both the module and the truck.

Service Modules

4x2/4x4

Service Trucks

6x4/6x6

Off-Road Service Trucks

8x4/8x8

On-Road Service Trucks

10x4/10x6

Off-Road Service Trucks

Fuel Modules

4x2/4x4 Fuel Trucks

6x4/6x6 Fuel Trucks

8x4/8x8 Fuel Trucks

10x4/10x6 Fuel Trucks

Product Pumping & Dispensing Equipment

Our range of service modules offer a variety of dispensing systems to cater for all applications and are designed for servicing performance to keep machine downtime to a minimum while ensuring reliable and safe operation.

All modules feature options for:

Hydraulic, pneumatic or spring retractable hose reels

Hydraulic driven oil pumping circuits delivering up to 70 L/min (100 L/min on request)

Pneumatic driven oil pumping circuits delivering up to 50 L/min

Hydraulic driven diesel pumping circuit delivering up to 800 L/min

Pneumatic driven diesel pumping circuit delivering up to 250 L/min

Hydraulic or pneumatic driven grease pumping circuits

High-capacity product filtration

Low product level automatic pump shut-off to prevent pumps running dry

Overfill protection on module fill points

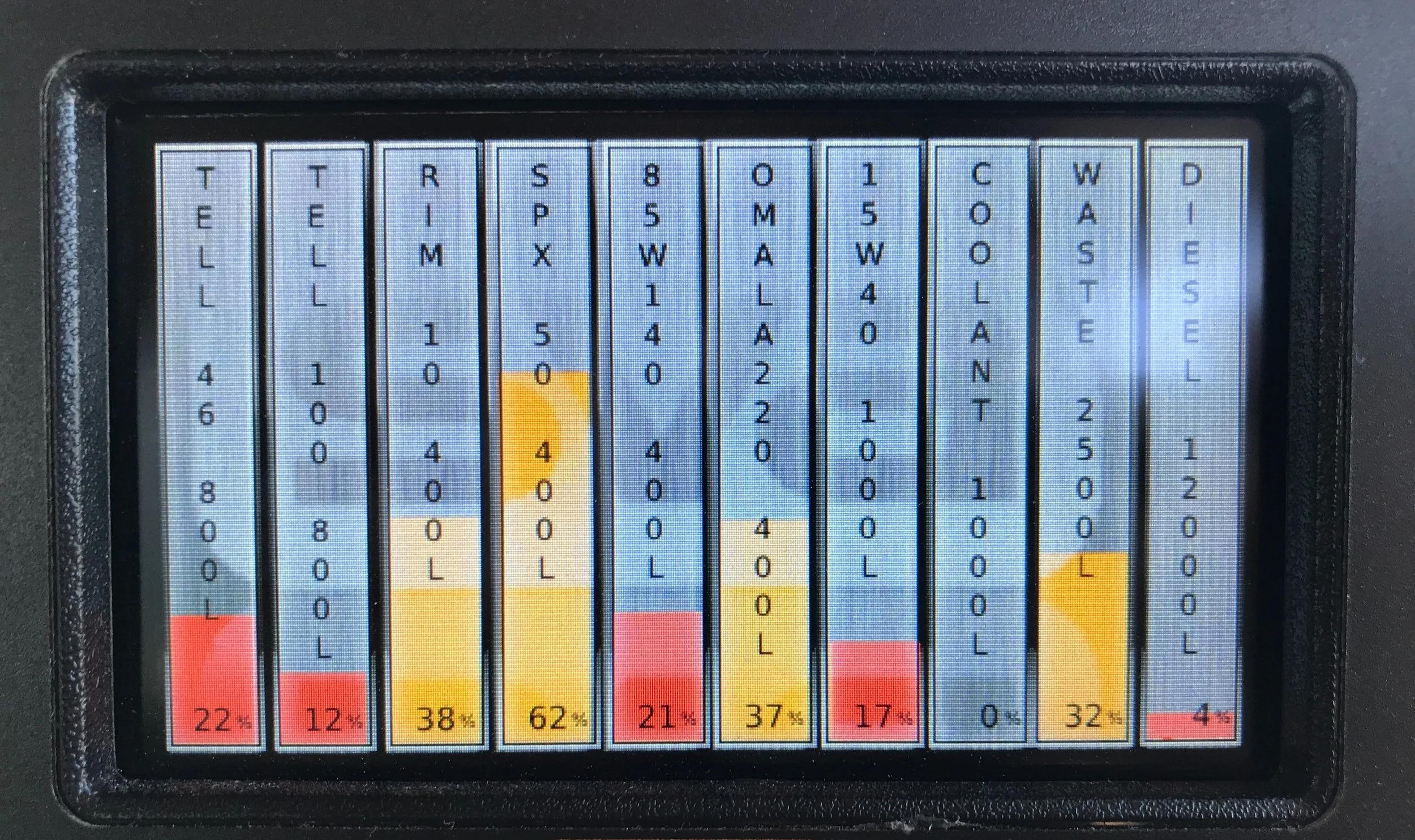

Level Monitoring

Adblue storage and dispensing

Product dispensing metering

Grease heating for high efficiency dispensing

Hydraulic or diesel driven air-on-demand compressor

Pneumatic diaphragm pumps for coolant and waste

Hydraulic driven high pressure wash system

Fold out high flow delivery fuel boom delivering up to 800 L/min

Diesel fill system capable of receiving at 2,500 L/min

High-Flow Fuel Boom

The high-flow fuel boom provides up to 800 L/min of diesel delivery for rapid refuelling of large dig units to maximise the production time of mining equipment. The swing out design of the boom is easily operated via a dead-man brake release control to allow the operator to quickly and safely set-up for dispensing.

Level Monitoring & Overfill Protection

Level monitoring provides the operator with a visual display of all product levels from the operator’s cab or product dispensing cabinet, allowing the operator to understand individual product compartment levels during filling and dispensing.

The system controls high level shut-off to prevent overfilling of compartments, and low level shut-off of individual hydraulic driven dispensing circuits to prevent dry-running of pumping components.

Integrated ROPS - Uniquely SVA

SVA first developed the module integrated ROPS in 2002. This unique feature utilises high tensile steel and specialised chassis mounts to create a simpler, lighter weight solution compared to conventional chassis mounted ROPS structures.

Safety Maintenance Access

Regular maintenance tasks such as replacing system filters or tank top breathers are made easier by providing safe access, and our service body is designed with safe maintenance in mind.

Designed and built for longevity

Selection of the highest quality components ensures reliability throughout the module’s service life.

We believe value is demonstrated through a low whole-of-life cost by providing a product that can be refurbished for multiple service lives.

All of our on-highway service truck modules can be installed to carrier chassis’ or packaged and shipped to anywhere in Australia.

Contact us for more information on any of our service truck modules.